Alumina Washers

Alumina Washers

Applications that require a material that is non-conductive as well as rust, heat, and wear resistant rely on the strength and durability of ceramics. Having the ability to be shaped and formed to fit any application, ceramics are an ideal choice for insulating and securing fittings.

An advancement in ceramic technology is the development of the ceramic washer, which is the ideal choice for insulating a connection and providing a tight seamless union between surfaces. Unlike traditional washers, once an alumina ceramic washer is installed, it remains tightly locked in place and does not wear or suffer any form of atmospheric damage.

What is an Alumina Ceramic Washer?

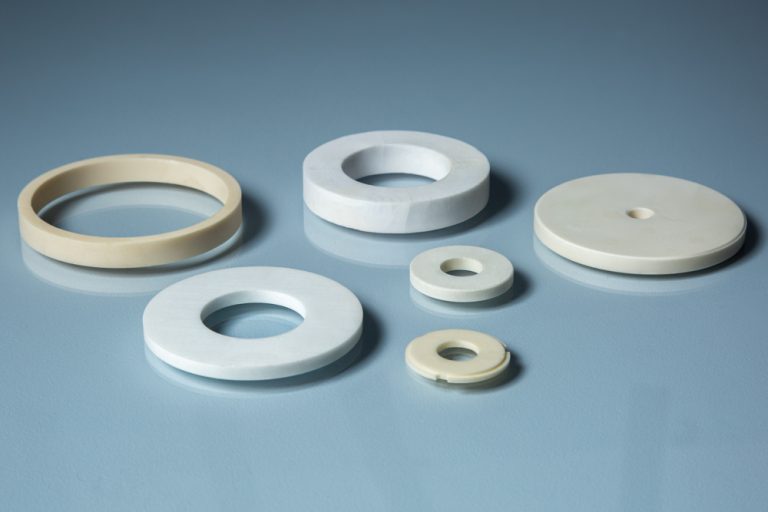

A ceramic washer has the same shape and configuration of all washers and can be produced with flanged, grooved, plain, slotted, or tube eyelets. Since ceramic material can be shaped and formed to any size or dimensions, alumina ceramic washers are the first choice for harsh, stressful, and hazardous conditions.

Basic ceramic material is made from natural elements that have been hardened by a heat treatment to remove contaminants and strengthen the chemical bonds of the ceramic. It is this process that produces the exceptionally durable material that is so vital to industrial and manufacturing processes.

Washers made from alumina ceramic have the same properties that have made ceramic such an important part of product and component production. The introduction of ceramic washers is the next step in the implementation of ceramic as a factor in construction and assembly operations.

Why Ceramic Washers?

All washers serve the same function, a thin plate with a hole that distributes and spreads the load of a threaded fastener such as a bolt, screw, or nut. They are also used as spacers, pads, locking devices, and a means for suppressing vibrations.

The traditional view of a washer is a flat metal disk with a hole in the middle that is placed around a bolt or screw as it is inserted, connected, and tightened. Though this is a common interpretation, metal washers wear, rust, and deteriorate over time, which necessitates replacing them. In critical applications, the replacement process can be tedious if the washer has been in place for several years.

All the negative features of metal washers are eliminated with ceramic washers, which are made from natural materials that do not suffer the effects of aging. Every form and shape of washer found in metal washers can be produced in alumina washers. The distinguishing features are its excellent, exceptional, and undeniable durability.

Types of Ceramic Materials Used for Ceramic Washers

As with metals, there is more than one type of ceramic used to make ceramic washers. All the various forms can be shaped, formed, and manufactured to fit the needs of a specific application. The two most common types are Alumina Oxide (Al2O3) and Zirconia oxide (ZrO2).

Between alumina oxide and zirconia oxide, alumina oxide is the most widely used. Ceramic washers made from alumina oxide are ideal for electrical insultation due to their mechanical strength as well as their wear and chemical resistance.

An advantage of zirconia oxide is its fine grain smooth surface that can form a tight and secure seal for surface connections. It has exceptional strength and toughness with a high-quality appearance. Zirconia oxide ceramic washers have a usable temperature range of 3812o F or 2100o C with a melting point of 4900o F or 2700o C, which is the reason that it is so thermal resistant.

Regardless of the ceramic material, ceramic washers are available as flat, lock, vented, and Belleville washers to name a few. Whatever configuration of washer that can be made from metal can be manufactured as a ceramic washer.

Segmenting by dimension will alter the order of part numbers.

| ITEM# | OD | ID | THICKNESS | OD | ID | THICKNESS |

|---|---|---|---|---|---|---|

| ALW00600 | 0.250 in | 0.135 in | 0.020 in | 6.35 mm | 3.429 mm | 0.508 mm |

| ALW00601 | 0.300 in | 0.135 in | 0.060 in | 7.62 mm | 3.429 mm | 1.524 mm |

| ALW00301 | 0.150 in | 0.085 in | 0.015 in | 3.81 mm | 2.159 mm | 0.381 mm |

| ALW00267 | 0.165 in | 0.135 in | 0.125 in | 4.191 mm | 3.429 mm | 3.175 mm |

| ALW00612 | 0.187 in | 0.047 in | 0.020 in | 4.7498 mm | 1.1938 mm | 0.508 mm |

| ALW00268 | 0.188 in | 0.062 in | 0.125 in | 4.7752 mm | 1.5748 mm | 3.175 mm |

| ALW00270 | 0.188 in | 0.094 in | 0.050 in | 4.7752 mm | 2.3876 mm | 1.27 mm |

| ALW00293 | 0.236 in | 0.118 in | 0.157 in | 5.9944 mm | 2.9972 mm | 3.9878 mm |

| ALW00282 | 0.250 in | 0.125 in | 0.125 in | 6.35 mm | 3.175 mm | 3.175 mm |

| ALW00266 | 0.252 in | 0.205 in | 0.100 in | 6.4008 mm | 5.207 mm | 2.54 mm |

| ALW00518 | 0.312 in | 0.250 in | 0.375 in | 7.9248 mm | 6.35 mm | 9.525 mm |

| ALW00607 | 0.314 in | 0.189 in | 0.065 in | 7.9756 mm | 4.8006 mm | 1.651 mm |

| ALW-CERAC4 | 0.315 in | 0.157 in | 0.394 in | 8.001 mm | 3.9878 mm | 10.0076 mm |

| ALW-450JH572 | 0.500 in | 0.317 in | 0.125 in | 8.0518 mm | 12.7 mm | 3.175 |

| ALW00515 | 0.320 in | 0.172 in | 0.0375 in | 8.128 mm | 4.3688 mm | 0.9525 mm |

| ALW00500 | 0.350 in | 0.250 in | 0.835 in | 8.89 mm | 6.35 mm | 21.209 mm |

| ALW00279 | 0.370 in | 0.175 in | 0.100 in | 9.398 mm | 4.445 mm | 2.54 mm |

| ALW00519 | 0.375 in | 0.125 in | 0.030 in | 9.525 mm | 3.175 mm | 0.762 mm |

| ALW00283 | 0.375 in | 0.250 in | 0.125 in | 9.525 mm | 6.35 mm | 3.175 mm |

| ALW00299 | 0.375 in | 0.190 in | 0.187 in | 9.525 mm | 4.826 mm | 4.7498 mm |

| ALW00524 | 0.590 in | 0.394 in | 0.590 in | 14.986 mm | 10.0076 mm | 14.986 mm |

| ALW00271 | 0.425 in | 0.312 in | 0.250 in | 10.795 mm | 7.9248 mm | 6.35 mm |

| ALW00606 | 0.437 in | 0.312 in | 0.250 in | 11.0998 mm | 7.9248 mm | 6.35 mm |

| ALW-CERAW12 | 0.472 in | 0.157 in | 0.157 in | 11.9888 mm | 3.9878 mm | 3.9878 mm |

| ALW00603 | 0.476 in | 0.170 in | 0.110 in | 12.0904 mm | 4.318 mm | 2.794 mm |

| ALW00604 | 0.499 in | 0.281 in | 0.106 in | 12.6746 mm | 7.1374 mm | 2.6924 mm |

| ALW00400 | 0.500 in | 0.250 in | 0.125 in | 12.7 mm | 6.35 mm | 3.175 mm |

| ALW00262 | 0.500 in | 0.100 in | 0.312 in | 12.7 mm | 2.54 mm | 7.9248 mm |

| ALW00263 | 0.500 in | 0.084 in | 0.312 in | 12.7 mm | 2.1336 mm | 7.9248 mm |

| ALW00264 | 0.500 in | 0.140 in | 0.438 in | 12.7 mm | 3.556 mm | 11.1252 mm |

| ALW00273 | 0.500 in | 0.250 in | 0.062 in | 12.7 mm | 6.35 mm | 1.5748 mm |

| ALW00281 | 0.500 in | 0.125 in | 0.125 in | 12.7 mm | 3.175 mm | 3.175 mm |

| ALW00298 | 0.500 in | 0.375 in | 0.187 in | 12.7 mm | 9.525 mm | 4.7498 mm |

| ALW00407 | 0.500 in | 0.200 in | 0.125 in | 12.7 mm | 5.08 mm | 3.175 mm |

| ALW00611 | 0.500 in | 0.187 in | 0.250 in | 12.7 mm | 4.7498 mm | 6.35 mm |

| ALW00623 | 0.500 in | 0.125 in | 0.312 in | 12.7 mm | 3.175 mm | 7.9248 mm |

| ALW00514 | 0.551 in | 0.224 in | 0.197 in | 13.9954 mm | 5.6896 mm | 5.0038 mm |

| ALW00501 | 0.558 in | 0.250 in | 0.131 in | 14.1732 mm | 6.35 mm | 3.3274 mm |

| ALW00288 | 0.625 in | 0.375 in | 0.188 in | 15.875 mm | 9.525 mm | 4.7752 mm |

| ALW00289 | 0.625 in | 0.250 in | 0.312 in | 15.875 mm | 6.35 mm | 7.9248 mm |

| ALW00620 | 0.625 in | 0.250 in | 0.375 in | 15.875 mm | 6.35 mm | 9.525 mm |

| ALW00608 | 0.702 in | 0.302 in | 0.040 in | 17.8308 mm | 7.6708 mm | 1.016 mm |

| ALW00609 | 0.702 in | 0.189 in | 0.040 in | 17.8308 mm | 4.8006 mm | 1.016 mm |

| ALW00525 | 0.740 in | 0.480 in | 0.250 in | 18.796 mm | 12.192 mm | 6.35 mm |

| ALW00510 | 0.740 in | 0.500 in | 0.130 in | 18.796 mm | 12.7 mm | 3.302 mm |

| ALW-60-17WAL | 0.750 in | 0.375 in | 0.250 in | 19.05 mm | 9.525 mm | 6.35 mm |

| ALW00296 | 0.750 in | 0.562 in | 0.375 in | 19.05 mm | 14.2748 mm | 9.525 mm |

| ALW00502 | 1.250 in | 0.750 in | 0.250 in | 31.75 mm | 19.05 mm | 6.35 mm |

| ALW00503 | 1.250 in | 0.750 in | 0.250 in | 31.75 mm | 19.05 mm | 6.35 mm |

| ITEM# | OD | ID | THICKNESS | OD | ID | THICKNESS |

| ITEM# | OD | ID | THICKNESS | OD | ID | THICKNESS |

|---|---|---|---|---|---|---|

| ALW00616 | 0.750 in | 0.250 in | 0.157 in | 19.05 mm | 6.35 mm | 4 mm |

| ALW00618 | 0.750 in | 0.250 in | 0.064 in | 19.05 mm | 6.35 mm | 1.6256 mm |

| ALW00290 | 0.765 in | 0.560 in | 0.250 in | 19.431 mm | 14.224 mm | 6.35 mm |

| ALW00286 | 0.812 in | 0.501 in | 0.125 in | 20.6248 mm | 12.7254 mm | 3.175 mm |

| ALW00506 | 0.875 in | 0.315 in | 0.187 in | 22.225 mm | 8.001 mm | 4.7498 mm |

| ALW-60-270 | 0.875 in | 0.312 in | 0.187 in | 22.225 mm | 7.9248 mm | 4.7498 mm |

| ALW00517 | 0.875 in | 0.266 in | 0.250 in | 22.225 mm | 6.7564 mm | 6.35 mm |

| ALW00512 | 0.972 in | 0.319 in | 0.394 in | 24.6888 mm | 8.1026 mm | 10.0076 mm |

| ALW00297 | 1.000 in | 0.750 in | 0.375 in | 25.4 mm | 19.05 mm | 9.525 mm |

| ALW00622 | 1.000 in | 0.750 in | 0.157 in | 25.4 mm | 19.05 mm | 2 mm |

| ALW00504 | 1.000 in | 0.500 in | 0.125 in | 25.4 mm | 12.7 mm | 3.175 mm |

| ALW00505-.352 | 1.000 in | 0.219 in | 0.352 in | 25.4 mm | 5.5626 mm | 8.9408 mm |

| ALW00505-.354 | 1.000 in | 0.219 in | 0.354 in | 25.4 mm | 5.5626 mm | 8.9916 mm |

| ALW00505-.488 | 1.000 in | 0.219 in | 0.488 in | 25.4 mm | 5.5626 mm | 12.3952 mm |

| ALW00505-.496 | 1.000 in | 0.219 in | 0.496 in | 25.4 mm | 5.5626 mm | 12.5984 mm |

| ALW00513 | 1.000 in | 0.675 in | 0.125 in | 25.4 mm | 17.145 mm | 3.175 mm |

| ALW00269 | 1.000 in | 0.438 in | 0.250 in | 25.4 mm | 11.1252 mm | 6.35 mm |

| ALW00287 | 1.000 in | 0.255 in | 0.250 in | 25.4 mm | 6.477 mm | 6.35 mm |

| ALW00523 | 1.024 in | 0.789 in | 0.030 in | 26.0096 mm | 20.0406 mm | 0.762 mm |

| ALW00599 | 1.050 in | 0.440 in | 0.220 in | 26.67 mm | 11.176 mm | 5.588 mm |

| ALW00602 | 1.105 in | 0.438 in | 0.220 in | 28.067 mm | 11.1 mm | 5.588 mm |

| ALW00405 | 1.172 in | 0.526 in | 0.250 in | 29.7688 mm | 13.3604 mm | 6.35 mm |

| ALW00610 | 1.181 in | 0.197 in | 0.157 in | 29.9974 mm | 5.0038 mm | 3.9878 mm |

| ALW00521 | 1.250 in | 1.000 in | 0.190 in | 31.75 mm | 25.4 mm | 4.826 mm |

| ALW00522 | 1.250 in | 1.000 in | 0.190 in | 31.75 mm | 25.4 mm | 4.826 mm |

| ALW00275 | 1.250 in | 1.000 in | 0.500 in | 31.75 mm | 25.4 mm | 12.7 mm |

| ALW00511 | 1.378 in | 1.189 in | 0.102 in | 35.0012 mm | 30.2006 mm | 2.5908 mm |

| ALW00300 | 1.500 in | 0.875 in | 0.200 in | 38.1 mm | 22.225 mm | 5.08 mm |

| ALW00406 | 1.500 in | 0.750 in | 0.200 in | 38.1 mm | 19.05 mm | 5.08 mm |

| ALW00516 | 1.500 in | 0.437 in | 0.250 in | 38.1 mm | 11.0998 mm | 6.35 mm |

| ALW00102 | 1.500 in | 0.620 in | 0.200 in | 38.1 mm | 15.748 mm | 5.08 mm |

| ALW00274 | 1.500 in | 0.500 in | 0.250 in | 38.1 mm | 12.7 mm | 6.35 mm |

| ALW00619 | 1.575 in | 0.433 in | 0.157 in | 40.005 mm | 10.9982 mm | 3.9878 mm |

| ALW00614 | 1.690 in | 1.380 in | .060 in | 42.926 mm | 35.052 mm | 1.524 mm |

| ALW00621 | 1.750 in | 1.500 in | 0.150 in | 44.45 mm | 38.1 mm | 3.81 mm |

| ALW00520 | 2.000 in | 1.100 in | 0.260 in | 50.8 mm | 27.94 mm | 6.604 mm |

| ALW00520-1 | 2.000 in | 1.225 in | 0.260 in | 50.8 mm | 31.115 mm | 6.604 mm |

| ALW00615 | 2.000 in | 1.000 in | 0.250 in | 50.8 mm | 25.4 mm | 6.35 mm |

| ALW00617 | 2.000 in | 1.500 in | 0.250 in | 50.8 mm | 38.1 mm | 6.35 mm |

| ALW-5903185 | 2.130 in | 0.330 in | 0.250 in | 54.102 mm | 8.382 mm | 6.35 mm |

| ALW00508-1/4 | 2.250 in | 0.625 in | 0.250 in | 57.15 mm | 15.875 mm | 6.35 mm |

| ALW00508-1/8 | 2.250 in | 0.625 in | 0.125 in | 57.15 mm | 15.875 mm | 3.175 mm |

| ALW00284 | 2.500 in | 1.100 in | 0.260 in | 63.5 mm | 27.94 mm | 6.604 mm |

| ALW00284-1 | 2.500 in | 1.225 in | 0.260 in | 63.5 mm | 31.115 mm | 6.604 mm |

| ALW00285 | 2.500 in | 0.500 in | 0.260 in | 63.5 mm | 12.7 mm | 6.604 mm |

| ALW00509 | 2.824 in | 2.364 in | 0.220 in | 71.7296 mm | 60.0456 mm | 5.588 mm |

| ALW00613 | 3.000 in | 1.000 in | 0.250 in | 76.2 mm | 25.4 mm | 6.35 mm |

| ALW00624 | 3.187 in | 0.270 in | 0.270 in | 80.9498 mm | 6.858 mm | 6.858 mm |

| ALW-425M9M23 | 3.430 in | 2.430 in | 0.250 in | 87.122 mm | 61.722 mm | 6.35 mm |

| ALW00244 | 3.550 in | 2.650 in | 0.230 in | 90.17 mm | 67.31 mm | 5.842 mm |

| ITEM# | OD | ID | THICKNESS | OD | ID | THICKNESS |