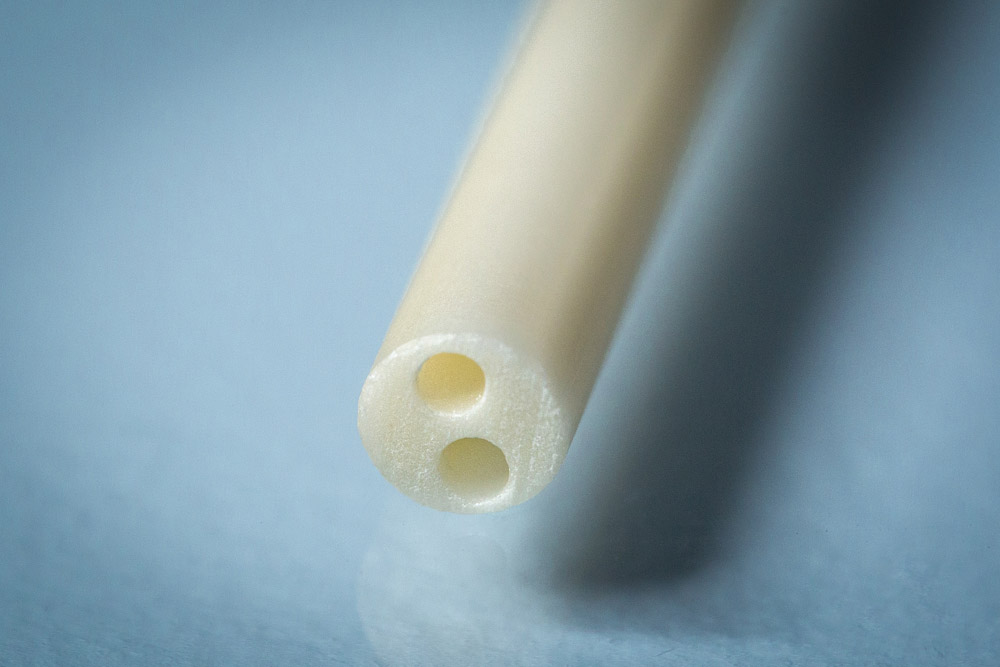

Alumina Double Bore Tubes

| Item # | Inner Diameter | Outer Diameter |

| ADB503 | 0.005 in | 0.032 in |

| ADB504 | 0.010 in | 0.047 in |

| ADB505 | 0.016 in | 0.062 in |

| ADB506 | 0.010 in | 0.047 in |

| ADB507 | 0.025 in | 0.093 in |

| ADB508 | 0.020 in | 0.125 in |

| ADB509 | 0.032 in | 0.125 in |

| ADB510 | 0.040 in | 0.125 in |

| ADB511 | 0.032 in | 0.156 in |

| ADB512 | 0.040 in | 0.156 in |

| ADB512-1 | 0.047 in | 0.156 in |

| ADB513 | 0.032 in | 0.188 in |

| ADB514 | 0.040 in | 0.188 in |

| ADB515 | 0.047 in | 0.188 in |

| ADB516 | 0.062 in | 0.188 in |

| ADB517 | 0.050 in | 0.200 in |

| ADB518 | 0.040 in | 0.250 in |

| ADB519 | 0.062 in | 0.250 in |

| ADB520 | 0.078 in | 0.250 in |

| ADB521 | 0.093 in | 0.250 in |

| ADB522 | 0.062 in | 0.312 in |

| ADB523 | 0.078 in | 0.312 in |

| ADB524 | 0.125 in | 0.375 in |

| ADB525 | 0.156 in | 0.500 in |

Applications of Alumina Double Bore Tubes in Specialized Industries<

Alumina double bore tubes, engineered from high-purity aluminum oxide, are critical components in industries requiring precision, durability, and resistance to extreme conditions. At LSP Industrial Ceramics, we provide custom alumina double bore tubes designed for specialized applications, offering unmatched performance in harsh environments. With their unique dual-channel design, these alumina ceramic tubes are ideal for advanced industrial and laboratory setups. Let’s explore the key uses of alumina double bore tubes and why LSP Ceramics is your trusted alumina tube supplier.

What Are Alumina Double Bore Tubes?

Alumina double bore tubes are alumina ceramic tubes featuring two parallel channels within a single tube, made from high-purity aluminum oxide (Al₂O₃). This design allows for the simultaneous passage of multiple media or components, while the alumina ceramic material ensures resistance to high temperatures, corrosion, and electrical conductivity. At LSP Industrial Ceramics, our alumina double bore tubes are available in purities of 99%, 99.5%, and 99.7%, tailored to your specific needs.

Key Uses of Alumina Double Bore Tubes

- Thermocouple Protection in High-Temperature Environments

- Electrical Insulation for Dual-Channel Systems

- Fluid and Gas Separation in Controlled Environments

- Vacuum and High-Pressure Systems