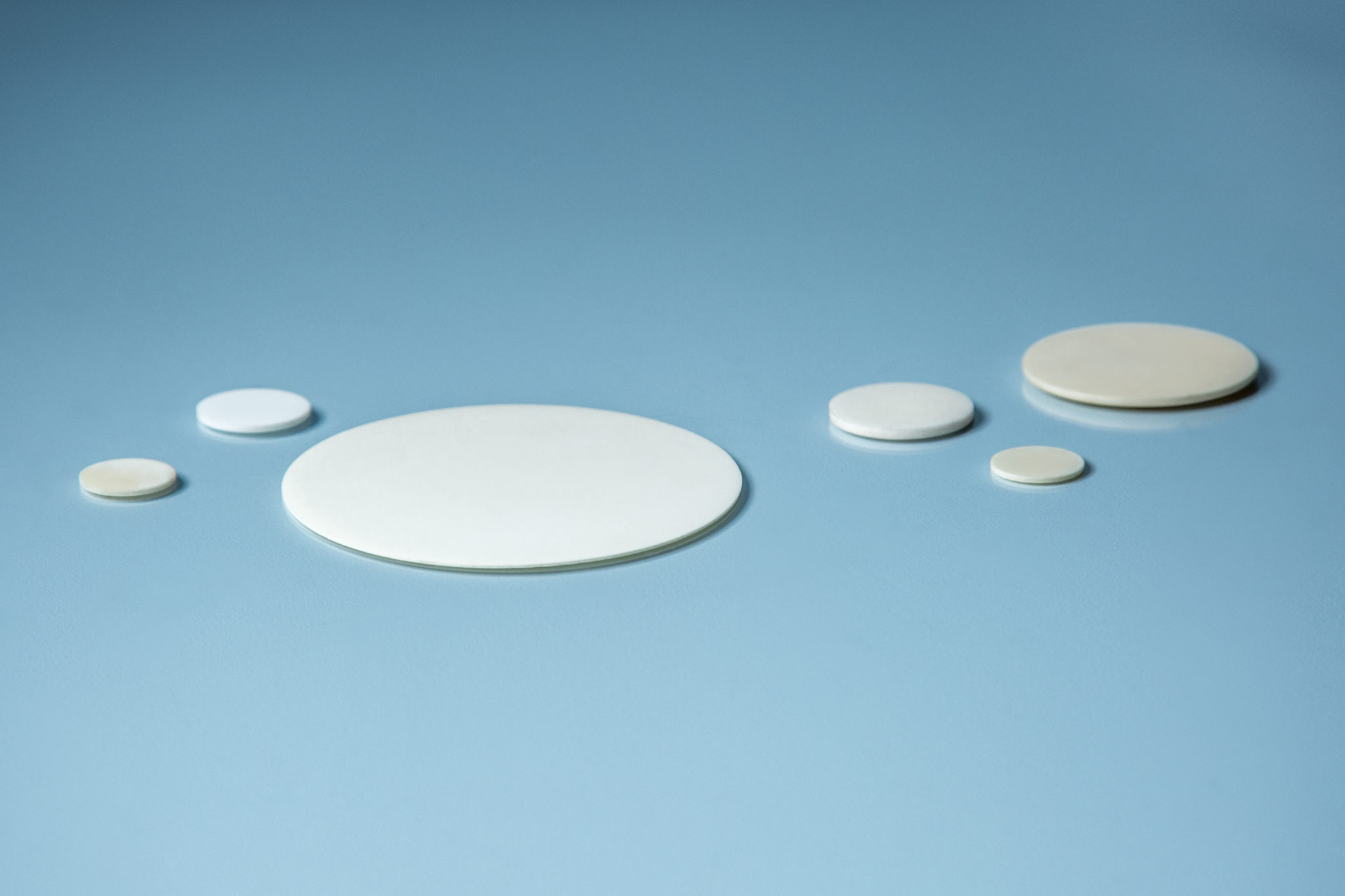

Alumina Round Disc

| ITEM# DIS | DIAMETER | THICKNESS |

|---|---|---|

| DIS001 | 25 | 1.5 |

| DIS002 | 32 | 2 |

| DIS003 | 38 | 2 |

| DIS004 | 51 | 2 |

| DIS005 | 64 | 3 |

| DIS006 | 76 | 3 |

| DIS007 | 89 | 4 |

| DIS008 | 102 | 4 |

| DIS009 | 127 | 5 |

| DIS010 | 152 | 5 |

| ITEM# DIS | DIAMETER | THICKNESS |

Material Characteristics and Functional Performance

High purity alumina offers a combination of hardness, wear resistance, and thermal endurance that makes these discs suitable for demanding applications. The material maintains structural integrity under elevated temperatures and resists degradation when exposed to corrosive media. Low porosity helps prevent contamination, while stable dielectric properties support use in electrical and electronic assemblies. These characteristics make alumina discs a dependable choice for environments where metals, polymers, or lower grade ceramics cannot maintain performance.

Geometry and Design Considerations

The round profile of these discs provides even heat exposure and predictable thermal gradients, making them suitable for furnace platforms, support plates, and high temperature fixtures. Their smooth surfaces and consistent thickness support precise placement in assemblies, while the uniform diameter ensures compatibility with a variety of equipment configurations. This geometry is also beneficial for polishing, grinding, and material testing applications where consistent contact surfaces are required.

Application Environments

Alumina round discs are used across industries such as materials research, semiconductor processing, chemical production, and advanced manufacturing. Common uses include substrate carriers, thermal support plates, electrical insulators, and components for high temperature reaction systems. Their durability and purity make them suitable for workflows involving sintering, calcination, sample preparation, and analytical testing. These discs also support applications in optics, electronics, and ceramic component fabrication.

Customization and Sizing Flexibility

A wide range of diameters and thicknesses can be produced to meet specific operational requirements. Custom configurations are available for users who need specialized dimensions, surface finishes, or purity levels. This flexibility ensures compatibility with unique furnace designs, mounting systems, and process conditions.

FAQs

What are Alumina Round Discs Commonly Used For?

They are used as thermal support plates, electrical insulators, substrate carriers, and components in high temperature processing systems.

Can These Discs Withstand High Temperatures?

Yes. High purity alumina maintains structural stability under elevated temperatures and supports repeated heating cycles.

Are Alumina Discs Suitable for Corrosive Environments?

Alumina’s resistance to acids, alkalis, and reactive compounds allows these discs to perform reliably in corrosive settings.

Is Custom Manufacturing Available for Round Discs?

Yes. Custom diameters, thicknesses, and purity levels can be produced to meet specific application requirements.