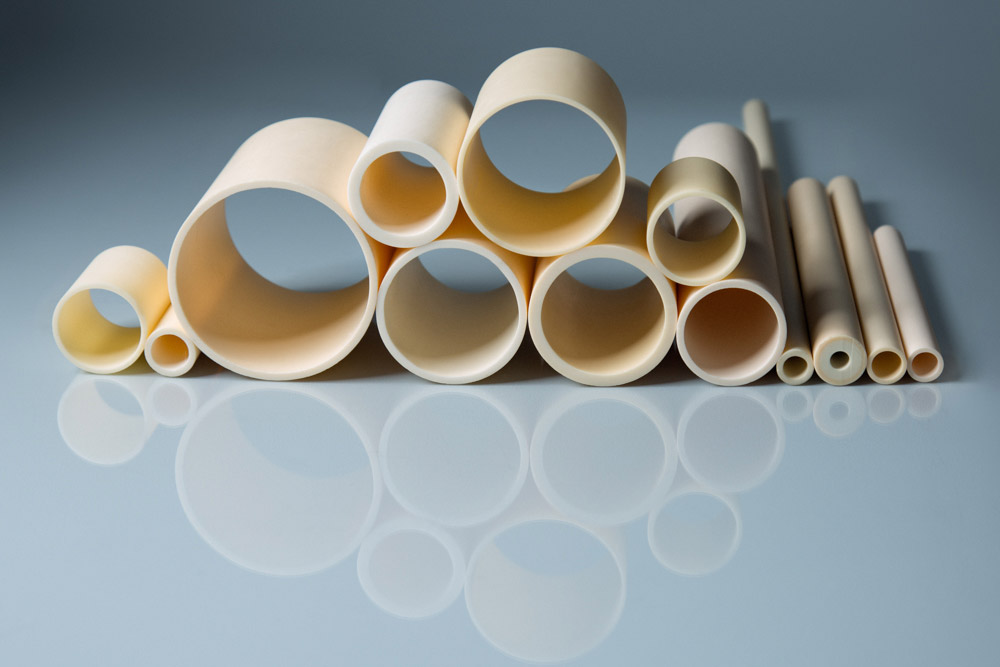

Alumina Single Bore Tubes

Segmenting by dimension will alter the order of part numbers.

| ITEM # | ID | OD | ID | OD |

|---|---|---|---|---|

| ASB00800 | 0.008 in | 0.025 in | 0.2 mm | 0.6 mm |

| ASB00801 | 0.012 in | 0.025 in | 0.3 mm | 0.6 mm |

| ASB00802 | 0.012 in | 0.032 in | 0.3 mm | 0.8 mm |

| ASB00803 | 0.014 in | 0.032 in | 0.4 mm | 0.8 mm |

| ASB00804 | 0.017 in | 0.047 in | 0.4 mm | 1.2 mm |

| ASB00805 | 0.020 in | 0.032 in | 0.5 mm | 0.8 mm |

| ASB00806 | 0.020 in | 0.035 in | 0.5 mm | 0.9 mm |

| ASB00807 | 0.020 in | 0.050 in | 0.5 mm | 1.3 mm |

| ASB00808 | 0.028 in | 0.052 in | 0.7 mm | 1.3 mm |

| ASB00809 | 0.032 in | 0.062 in | 0.8 mm | 1.6 mm |

| ASB00810 | 0.040 in | 0.078 in | 1.0 mm | 2.0 mm |

| ASB00811 | 0.040 in | 0.093 in | 1.0 mm | 2.4 mm |

| ASB00812 | 0.040 in | 0.188 in | 1.0 mm | 4.8 mm |

| ASB00813 | 0.047 in | 0.062 in | 1.2 mm | 1.6 mm |

| ASB00814 | 0.047 in | 0.078 in | 1.2 mm | 2.0 mm |

| ASB00815 | 0.050 in | 0.100 in | 1.3 mm | 2.5 mm |

| ASB00816 | 0.062 in | 0.093 in | 1.6 mm | 2.4 mm |

| ASB00817 | 0.062 in | 0.188 in | 1.6 mm | 4.8 mm |

| ASB00820 | 0.062 in | 0.125 in | 1.6 mm | 3.2 mm |

| ASB00821 | 0.062 in | 0.156 in | 1.6 mm | 4.0 mm |

| ASB00823 | 0.062 in | 0.250 in | 1.6 mm | 6.3 mm |

| ASB00818 | 0.068 in | 0.107 in | 1.7 mm | 2.7 mm |

| ASB00828 | 0.078 in | 0.156 in | 2.0 mm | 4.0 mm |

| ASB008281 | 0.039 in | 0.079 in | 1.0 mm | 2.0 mm |

| ASB00824 | 0.093 in | 0.125 in | 2.4 mm | 3.2 mm |

| ASB00825 | 0.093 in | 0.156 in | 2.4 mm | 4.0 mm |

| ASB00826 | 0.093 in | 0.188 in | 2.4 mm | 4.8 mm |

| ASB008261 | 0.093 in | 0.218 in | 2.4 mm | 5.5 mm |

| ASB00827 | 0.093 in | 0.250 in | 2.4 mm | 6.3 mm |

| ASB008271 | 0.050 in | 0.100 in | 1.3 mm | 2.5 mm |

| ASB00829 | 0.109 in | 0.219 in | 2.8 mm | 5.6 mm |

| ASB008291 | 0.059 in | 0.118 in | 1.5 mm | 3.0 mm |

| ASB00830 | 0.125 in | 0.188 in | 3.2 mm | 4.8 mm |

| ASB00831 | 0.125 in | 0.219 in | 3.2 mm | 5.6 mm |

| ASB00832 | 0.125 in | 0.250 in | 3.2 mm | 6.3 mm |

| ASB00833 | 0.125 in | 0.218 in | 3.2 mm | 5.5 mm |

| ASB008331 | 0.063 in | 0.125 in | 1.6 mm | 3.2 mm |

| ASB00834 | 0.156 in | 0.250 in | 4.0 mm | 6.3 mm |

| ASB00835 | 0.156 in | 0.312 in | 4.0 mm | 7.9 mm |

| ASB008351 | 0.079 in | 0.157 in | 2.0 mm | 4.0 mm |

| ASB00836 | 0.188 in | 0.375 in | 4.8 mm | 9.5 mm |

| ASB00837 | 0.188 in | 0.250 in | 4.8 mm | 6.3 mm |

| ASB00838 | 0.188 in | 0.312 in | 4.8 mm | 7.9 mm |

| ASB00839 | 0.188 in | 0.375 in | 4.8 mm | 9.5 mm |

| ASB00840 | 0.188 in | 0.500 in | 4.8 mm | 12.7 mm |

| ASB008401 | 0.118 in | 0.197 in | 3.0 mm | 5.0 mm |

| ASB00841 | 0.218 in | 0.312 in | 5.5 mm | 7.9 mm |

| ASB008411 | 0.118 in | 0.236 in | 3.0 mm | 6.0 mm |

| ASB008412 | 0.157 in | 0.236 in | 4.0 mm | 6.0 mm |

| ASB00842 | 0.250 in | 0.312 in | 6.3 mm | 7.9 mm |

| ASB00843 | 0.250 in | 0.375 in | 6.3 mm | 9.5 mm |

| ASB00844 | 0.250 in | 0.500 in | 6.3 mm | 12.7 mm |

| ASB008441 | 0.125 in | 0.250 in | 3.2 mm | 6.3 mm |

| ASB008442 | 0.157 in | 0.250 in | 4.0 mm | 6.3 mm |

| ASB008443 | 0.188 in | 0.250 in | 4.8 mm | 6.3 mm |

| ASB008444 | 0.157 in | 0.276 in | 4.0 mm | 7.0 mm |

| ASB008445 | 0.197 in | 0.276 in | 5.0 mm | 7.0 mm |

| ASB00845 | 0.312 in | 0.438 in | 7.9 mm | 11.1 mm |

| ASB00846 | 0.312 in | 0.500 in | 7.9 mm | 12.7 mm |

| ASB008461 | 0.197 in | 0.315 in | 5.0 mm | 8.0 mm |

| ASB008462 | 0.236 in | 0.354 in | 6.0 mm | 9.0 mm |

| ASB00847 | 0.375 in | 0.500 in | 9.5 mm | 12.7 mm |

| ASB008471 | 0.250 in | 0.375 in | 6.3 mm | 9.5 mm |

| ASB008472 | 0.236 in | 0.394 in | 6.0 mm | 10.0 mm |

| ASB008473 | 0.276 in | 0.394 in | 7.0 mm | 10.0 mm |

| ASB008474 | 0.276 in | 0.433 in | 7.0 mm | 11.0 mm |

| ASB008475 | 0.236 in | 0.472 in | 6.0 mm | 12.0 mm |

| ASB008476 | 0.315 in | 0.472 in | 8.0 mm | 12.0 mm |

| ASB008477 | 0.355 in | 0.472 in | 9.0 mm | 12.0 mm |

| ASB00848 | 0.500 in | 0.625 in | 12.7 mm | 15.9 mm |

| ASB00849 | 0.500 in | 0.680 in | 12.7 mm | 17.3 mm |

| ASB00850 | 0.500 in | 0.750 in | 12.7 mm | 19.1 mm |

| ASB008501 | 0.250 in | 0.500 in | 6.3 mm | 12.7 mm |

| ASB008502 | 0.375 in | 0.500 in | 9.5 mm | 12.7 mm |

| ASB008503 | 0.394 in | 0.551 in | 10.0 mm | 14.0 mm |

| ASB00851 | 0.562 in | 0.750 in | 14.3 mm | 19.1 mm |

| ASB008511 | 0.394 in | 0.591 in | 10.0 mm | 15.0 mm |

| ASB008512 | 0.433 in | 0.591 in | 11.0 mm | 15.0 mm |

| ASB00852 | 0.625 in | 0.875 in | 15.9 mm | 22.2 mm |

| ASB00853 | 0.472 in | 0.630 in | 12.0 mm | 16.0 mm |

| ASB00854 | 0.472 in | 0.669 in | 12.0 mm | 17.0 mm |

| ASB00855 | 0.437 in | 0.688 in | 11.1 mm | 17.5 mm |

| ASB00856 | 0.512 in | 0.750 in | 13.0 mm | 19.1 mm |

| ASB00857 | 0.500 in | 0.750 in | 12.7 mm | 19.1 mm |

| ASB00858 | 0.591 in | 0.787 in | 15.0 mm | 20.0 mm |

| ASB00859 | 0.630 in | 0.866 in | 16.0 mm | 22.0 mm |

| ASB00860 | 0.669 in | 0.866 in | 17.0 mm | 22.0 mm |

| ASB00861 | 0.709 in | 0.945 in | 18.0 mm | 24.0 mm |

| ASB00862 | 0.750 in | 1.000 in | 19.1 mm | 25.4 mm |

| ASB00863 | 0.669 in | 1.063 in | 17.0 mm | 27.0 mm |

| ASB00864 | 0.787 in | 1.063 in | 20.0 mm | 27.0 mm |

| ASB00865 | 0.886 in | 1.126 in | 22.5 mm | 28.6 mm |

| ASB00866 | 0.827 in | 1.181 in | 21.0 mm | 30.0 mm |

| ASB00867 | 0.906 in | 1.181 in | 23.0 mm | 30.0 mm |

| ASB00868 | 0.984 in | 1.260 in | 25.0 mm | 32.0 mm |

| ASB00869 | 1.125 in | 1.375 in | 28.6 mm | 34.9 mm |

| ASB00870 | 1.063 in | 1.378 in | 27.0 mm | 35.0 mm |

| ASB00871 | 1.181 in | 1.496 in | 30.0 mm | 38.0 mm |

| ASB00872 | 1.250 in | 1.500 in | 31.8 mm | 38.1 mm |

| ASB00873 | 1.181 in | 1.575 in | 30.0 mm | 40.0 mm |

| ASB00874 | 1.339 in | 1.654 in | 34.0 mm | 42.0 mm |

| ASB00875 | 1.500 in | 1.750 in | 38.1 mm | 44.5 mm |

| ASB00876 | 1.496 in | 1.811 in | 38.0 mm | 46.0 mm |

| ASB00877 | 1.625 in | 1.875 in | 41.3 mm | 47.6 mm |

| ASB00878 | 1.575 in | 1.969 in | 40.0 mm | 50.0 mm |

| ASB00879 | 1.575 in | 2.000 in | 40.0 mm | 50.8 mm |

| ASB00880 | 1.750 in | 2.000 in | 44.5 mm | 50.8 mm |

| ASB00881 | 2.000 in | 2.250 in | 50.8 mm | 57.1 mm |

| ASB00882 | 1.890 in | 2.283 in | 48.0 mm | 58.0 mm |

| ASB00883 | 1.969 in | 2.362 in | 50.0 mm | 60.0 mm |

| ASB00884 | 2.250 in | 2.500 in | 57.1 mm | 63.5 mm |

| ASB00885 | 2.165 in | 2.559 in | 55.0 mm | 65.0 mm |

| ASB00886 | 2.500 in | 2.750 in | 63.5 mm | 69.8 mm |

| ASB00887 | 2.362 in | 2.756 in | 60.0 mm | 70.0 mm |

| ASB00888 | 2.561 in | 2.956 in | 65.0 mm | 75.1 mm |

| ASB00889 | 2.750 in | 3.000 in | 69.8 mm | 76.2 mm |

| ASB00890 | 2.675 in | 3.150 in | 67.9 mm | 80.0 mm |

| ASB00891 | 3.125 in | 3.500 in | 79.4 mm | 88.9 mm |

| ASB00892 | 3.250 in | 3.500 in | 82.5 mm | 88.9 mm |

| ASB00893 | 3.650 in | 4.000 in | 92.7 mm | 101.6 mm |

| ITEM # | ID | OD | ID | OD |

What industry applications can Alumina Single Bore Tubes be used for?

Alumina Single Bore Tubes from LSP Industrial Ceramics are versatile, high-performance components with a wide range of applications across multiple industries. Crafted from premium aluminum oxide (Al₂O₃) with purity levels up to 99.5% or higher, these tubes deliver exceptional durability, thermal stability, and chemical resistance—making them a top choice for demanding environments.

Key Applications of Alumina Single Bore Tubes

- Thermocouple Protection: Alumina single bore tubes excel as protective sleeves for thermocouples in high-temperature settings. Their ability to withstand up to 1800°C ensures reliable temperature measurement in furnaces and kilns.

- Electrical Insulation: With dielectric properties, these ceramic tubes insulate electrical connections, safeguarding wiring in extreme conditions—ideal for power generation and electronics.

- Heat Exchangers: Their high thermal conductivity and resistance to thermal shock make them perfect for heat exchanger tubing, dissipating heat in industrial processes.

- Corrosion-Resistant Piping: The tubes’ resistance to acids, halogens, and aggressive chemicals suits them for handling corrosive substances in labs or plants.

- Furnace Components: Used as furnace tubes or liners, they endure intense heat and maintain structural integrity, supporting long-term reliability.

Industry Applications

- Aerospace: Alumina single bore tubes support high-pressure nozzles and insulators, meeting stringent durability standards for aircraft systems.

- Automotive: They’re used in sensor housings and exhaust systems, leveraging heat and wear resistance for precision parts.

- Chemical Processing: These tubes handle mixed acids and bromine in reactors and pipelines, ensuring corrosion-free performance.

- Electronics: They insulate components in semiconductor production, protecting against heat and electrical interference.

- Manufacturing: From laser tubes to wear-resistant guides, they enhance industrial equipment longevity.

Why Choose LSP Ceramics?

LSP Industrial Ceramics, a leader in advanced ceramics, stocks a vast inventory of alumina single bore tubes in various sizes—customizable to your specs. Their hardness, chemical stability, and longevity make them a staple for industries needing low-maintenance, high-performance solutions. Whether for furnace applications, electrical insulation, or chemical resistance, these tubes deliver unmatched value. Contact LSP Ceramics today to explore how alumina single bore tubes can elevate your operations!