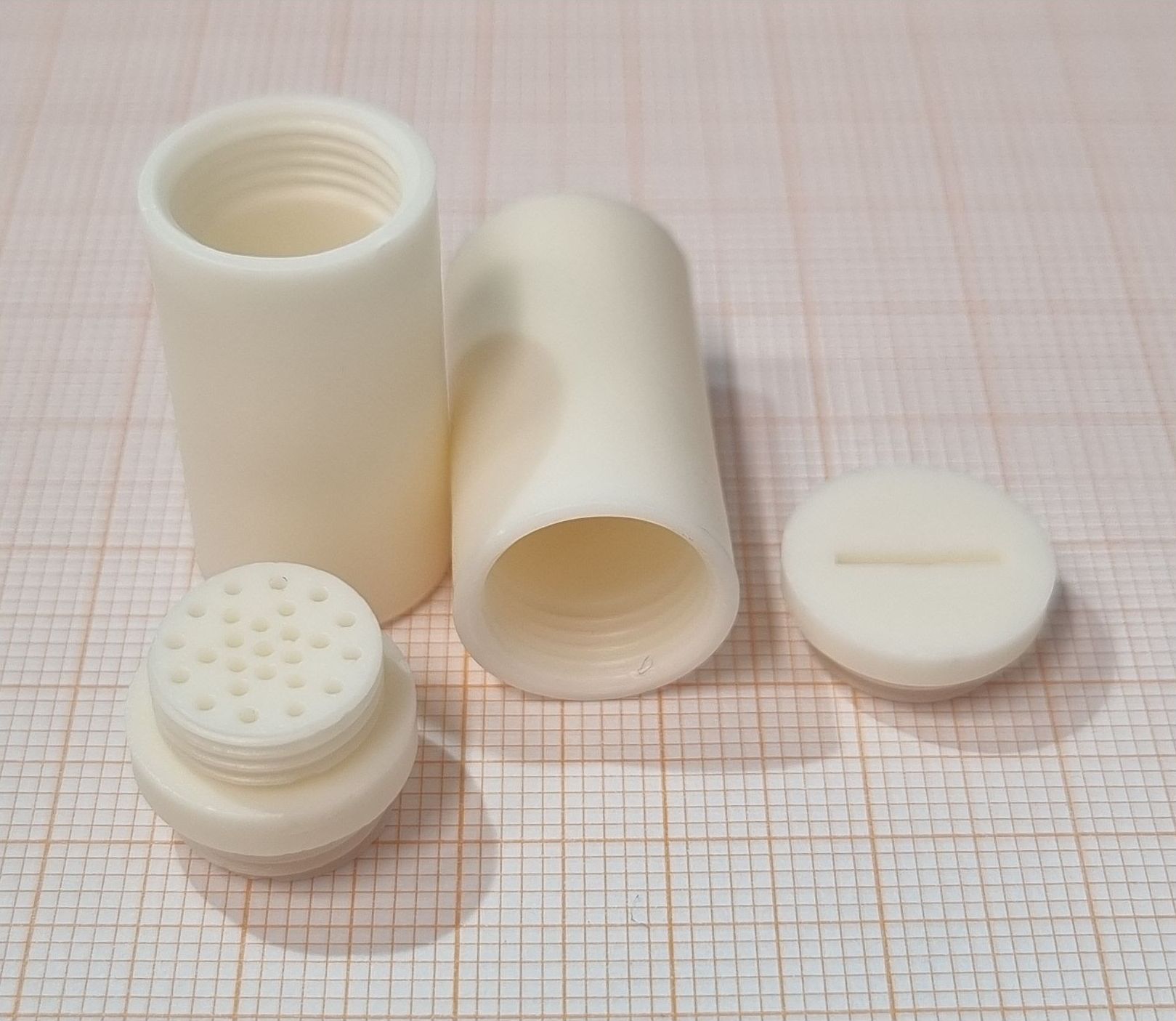

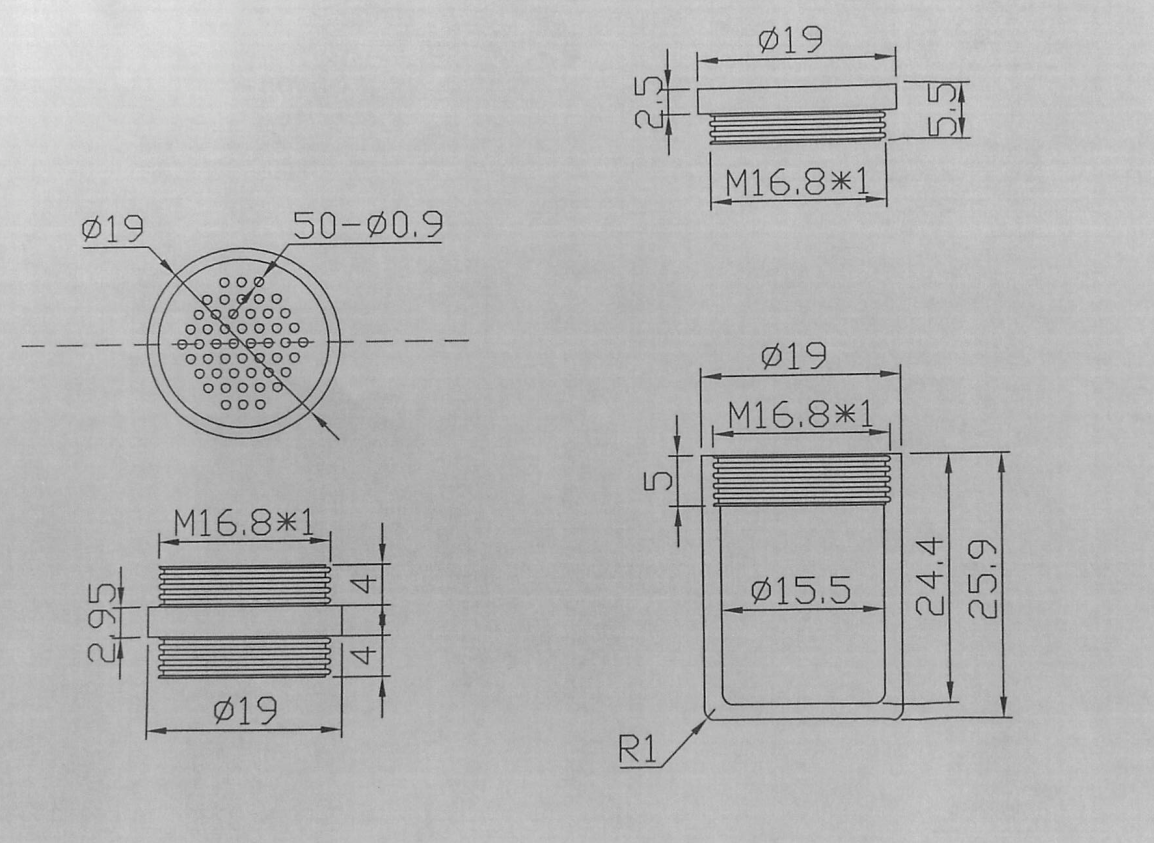

Canfield-Svanidze Crucible Sets (CSCS) are an advanced iteration of the Canfield Crucible Sets (CCS). They are specifically engineered for high-precision material synthesis in demanding industrial and research applications by LSP Ceramics. These sets feature a step-edge frit-disc to separate liquid from solid phases, with the addition of threads on both the crucible and frit, ensuring superior containment of liquids and vapors during synthesis and decanting processes. This makes CSCS particularly effective for experiments involving elements with high vapor pressure, such as gallium or mercury, where complete containment of the decanted liquid is critical. Researchers often use these sets as the primary containment vessel, placing them inside amorphous silica, tantalum, or niobium tubes to handle extreme conditions while maintaining structural integrity.

The applications of Canfield-Svanidze Sets are especially valuable in the growth of single crystals for advanced materials research, such as in the development of superconductors, semiconductors, and magnetic materials. Their design supports solution growth techniques by allowing precise separation of phases, which is essential for producing high-purity crystals used in electronics, aerospace, and energy sectors. The threaded design also minimizes material loss, making CSCS ideal for costly or hazardous substances. At LSP Industrial Ceramics, our CSCS are crafted with meticulous attention to detail, ensuring researchers can achieve consistent, reproducible results in their cutting-edge projects.

Enhanced Containment for High Vapor Pressure Elements

The threaded crucible and frit design of CSCS ensures superior containment of both liquids and vapors. This makes them particularly effective for experiments involving volatile elements such as gallium, mercury, or other materials where vapor control is critical to safety and precision.

Precision In Single Crystal Growth

CSCS are engineered to support solution growth techniques by enabling clean separation of solid and liquid phases. This precision is needed for producing high purity single crystals used in advanced applications like superconductors, semiconductors, and magnetic materials.

Adaptability To Extreme Conditions

Designed to be placed inside amorphous silica, tantalum, or niobium tubes, CSCS can withstand extreme synthesis environments. Their robust construction ensures structural integrity even under high temperatures and pressures, making them suitable for cutting edge research.

Cost Efficiency and Material Conservation

The threaded design minimizes material loss during decanting, allowing researchers to conserve costly or hazardous substances. This efficiency not only reduces waste but also makes CSCS a more economical choice for laboratories working with rare or expensive materials.

FAQ

What Makes Canfield Svanidze Crucible Sets Different from Standard CCS?

They feature threaded crucibles and frits, providing superior containment of liquids and vapors during synthesis.

Why Are CSCS Ideal for High Vapor Pressure Elements?

The threaded design prevents leakage and ensures safe handling of volatile materials like gallium or mercury.

Can CSCS Be Used in Extreme Environments?

Yes. They can be placed inside silica, tantalum, or niobium tubes to withstand high temperatures and pressures.

What Industries Benefit from CSCS Technology?

Electronics, aerospace, energy, and advanced materials research sectors rely on CSCS for high purity crystal growth.