Electrical Insulation in Wiring Systems

Steatite insulating beads and washers from LSP Industrial Ceramics are widely used in the electrical industry to provide reliable insulation for wiring systems. These components, made from magnesium silicate-based steatite, offer exceptional dielectric strength, preventing unwanted current flow and short circuits in high-voltage applications like power distribution panels and industrial machinery. Their “fish spine” interlocking design allows flexible insulation of bare wires in air or vacuum systems, ideal for protecting power lead wires in appliances, telecommunications equipment, and cathode-ray tubes. With high thermal resistance up to 1000°C, they ensure safety and durability in demanding environments.

Thermal Stability in High-Temperature Applications

Industries such as aerospace, automotive, and manufacturing rely on steatite insulating beads and washers for their thermal stability and low thermal conductivity. These ceramics withstand extreme temperatures without degrading, making them perfect for insulating heating elements, thermocouples, and band heaters in furnaces, ovens, and high-power electrical appliances. Their chemical inertness and corrosion resistance ensure long-term performance in harsh conditions, such as chemical processing plants or automotive engine compartments. Available in various sizes with customizable specifications, LSP’s beads and washers support precise insulation needs, enhancing equipment reliability and efficiency across these sectors.

Customizable Solutions for Specialized Needs

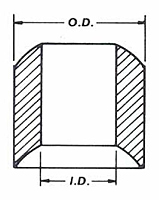

LSP’s steatite insulating beads and washers are highly customizable, catering to specialized industrial applications. Conforming to MIL-I-23264 standards, they can be ground to tolerances within 0.0005 inches and produced with custom diameters, lengths, and configurations, such as metallized surfaces or specific thread sizes. This flexibility benefits industries like defense and scientific research, where precise insulation is needed for high-frequency, low-loss components in radar systems or laboratory equipment. LSP’s rapid quote turnaround and extensive inventory ensure quick delivery, making them a trusted partner for manufacturers requiring tailored, high-performance insulation solutions.