Steatite Special Designs

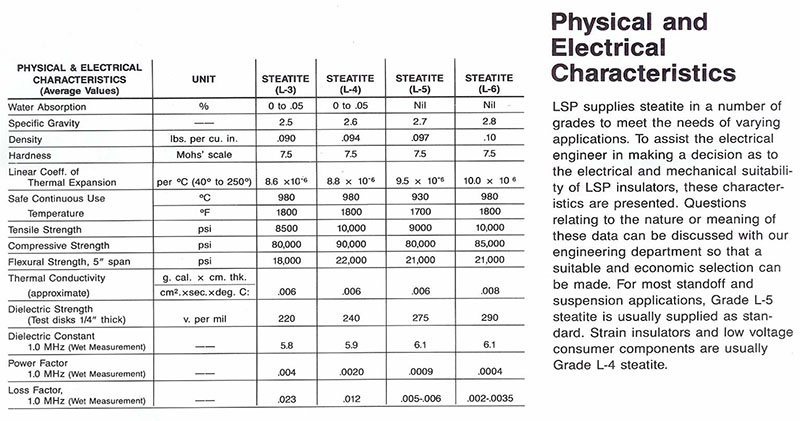

Physical and Electrical Characteristics

Applications for Steatite Special Designs

General Description: When an application demands special consideration in shape or performance, unusual designs are sometimes required. Applications in hostile environments, or where high reliability is required, are examples of special situations where LSP can provide help in supplying unique designs. Please send a print or sketch and a description of your application.

Tailored Solutions for Unique Applications

LSP Industrial Ceramics’ steatite special designs offer customers unparalleled flexibility for specialized applications across industries like aerospace, electronics, and medical manufacturing. These custom-engineered components, crafted from magnesium silicate-based steatite, provide exceptional dielectric strength and thermal stability, ideal for high-voltage or high-temperature environments. For instance, customers in the telecommunications sector benefit from custom insulators for antenna assemblies, ensuring reliable signal transmission without electrical interference. With over 30 years of experience, LSP collaborates closely with clients to create bespoke designs—such as intricate bushings or insulators with specific mounting configurations—delivering precise solutions that meet exact specifications while minimizing costly reworks or delays.

Enhanced Performance and Durability

Steatite special designs from LSP enhance customer applications through their superior material properties, including high mechanical strength, low thermal conductivity, and chemical inertness. These characteristics ensure long-lasting performance in harsh conditions, such as in chemical processing plants or high-temperature furnaces, where standard materials might fail. For example, defense industry clients use custom steatite insulators to protect sensitive electronics in extreme environments, reducing maintenance costs and downtime. LSP’s ability to grind components to tolerances within 0.0005 inches and incorporate features like threaded mounting holes ensures seamless integration, boosting reliability and efficiency for customers’ critical systems.

Streamlined Production and Cost Efficiency

LSP’s steatite special designs streamline production for customers by offering rapid prototyping and a vast inventory of unfired material, enabling quick turnaround without expensive tooling or setup charges. This is particularly valuable for industries like automotive or semiconductor manufacturing, where custom profiles for thermocouple components or electrical insulators are needed on tight schedules. LSP’s state-of-the-art manufacturing, including high-temperature firing (2372°F–2732°F) and in-house machining, ensures high-quality, cost-effective solutions. Customers benefit from rapid quote responses within 48 hours and scalable production, from one-off prototypes to large runs, optimizing budgets and accelerating project timelines.